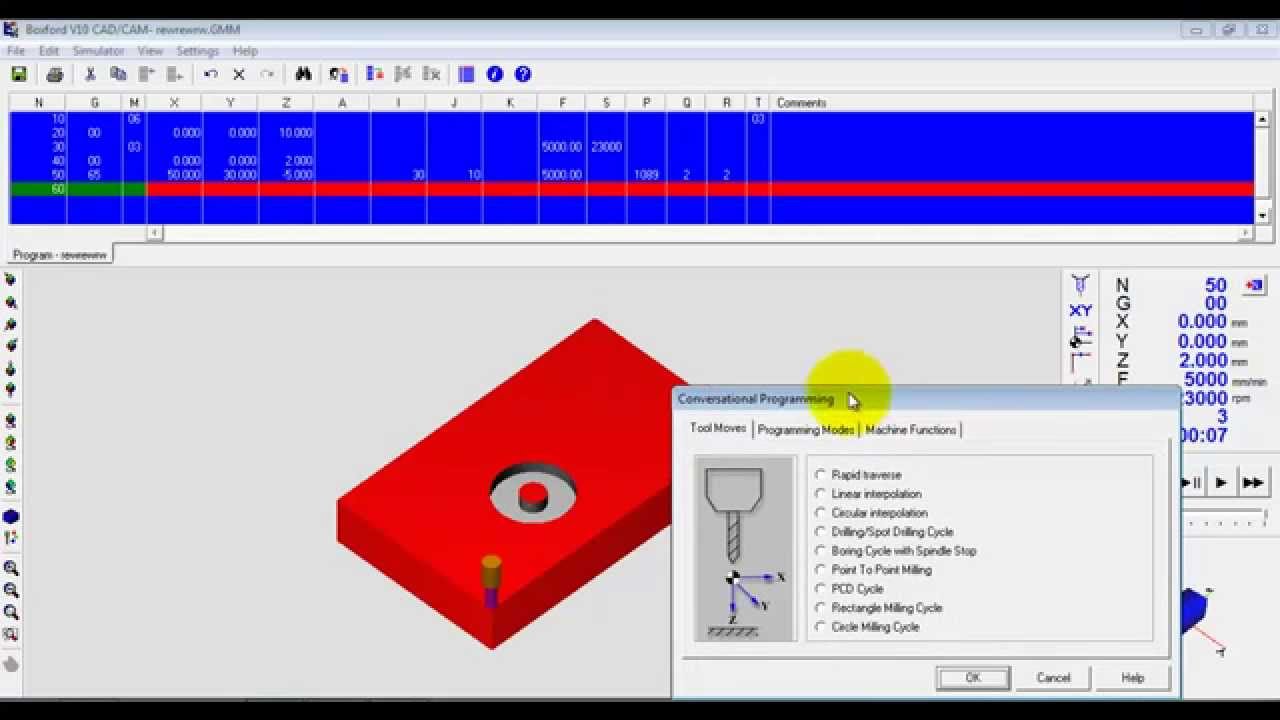

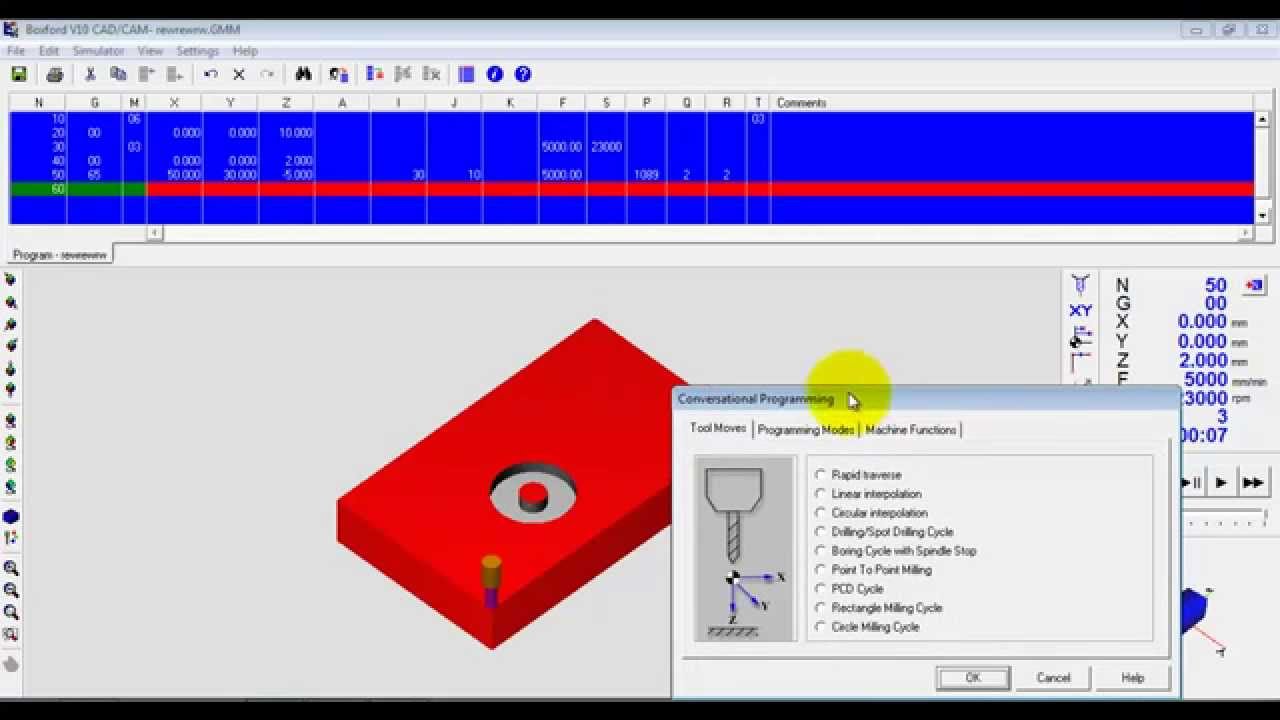

Concept of finding datum of the workpiece, for instance touching off the tool in x, y and z (z is very important).XYZ coordinate systems (on the Boxford CNC, x is left to right (+x is travelling right), y is towards / away from you (+y is travelling away from you), and z is down / up (+z is travelling up).You should try generating a tool path with a particular cutter, checking the toolpath visually and by simulation if your CAM software allows it, and finally posting the G-Code to the a g-code file (i.e.gcode extension).

Any CAM package, Fusion 360 is a good one if you are not sure. wax, modeling board) are very forgiving, while others (particularly metals) need to be just right for good results. Cutting materials - cutter speeds and feed rates - dependent on what you want to cut. DXF, IGES and STEP), and tool path files (i.e. The difference between CAD geometry files (i.e. In particular before coming you should learn a bit about We will be happy to help with explaining concepts but depending on your previous experience there is quite a lot to learn so you will get the most out of the session and the machine if you do some independent reading / practice. You should come to the session having some knowledge of CAD and CAM concepts and have used a CAD/CAM package such as Autodesk Fusion (free, works on Windows or OSX) or other package capable of generating g-code for CNC machining. Using a CNC requires a bit more background knowledge or learning than a laser cutter or 3d printer. If you can't attend your Induction session please remove your name from the roster. Reserving a place is on a first-come-first-served basis, so you'll need to be quick. Space is limited and you must reserve a place on this wiki page when a session is available - watch the Mailing List for announcements.

Any CAM package, Fusion 360 is a good one if you are not sure. wax, modeling board) are very forgiving, while others (particularly metals) need to be just right for good results. Cutting materials - cutter speeds and feed rates - dependent on what you want to cut. DXF, IGES and STEP), and tool path files (i.e. The difference between CAD geometry files (i.e. In particular before coming you should learn a bit about We will be happy to help with explaining concepts but depending on your previous experience there is quite a lot to learn so you will get the most out of the session and the machine if you do some independent reading / practice. You should come to the session having some knowledge of CAD and CAM concepts and have used a CAD/CAM package such as Autodesk Fusion (free, works on Windows or OSX) or other package capable of generating g-code for CNC machining. Using a CNC requires a bit more background knowledge or learning than a laser cutter or 3d printer. If you can't attend your Induction session please remove your name from the roster. Reserving a place is on a first-come-first-served basis, so you'll need to be quick. Space is limited and you must reserve a place on this wiki page when a session is available - watch the Mailing List for announcements.

This Induction is available to London Hackspace members only. This page is used to track Induction sessions for the Equipment/CNC_Mill.

0 kommentar(er)

0 kommentar(er)